FROM CONCEPT TO SERIES PRODUCTION

Mininni offers its customers the highest service level, as its aim is to be a proper partner in engineering and manufacturing rather than an ordinary supplier.

The company supports the customer in any single phase: from the very early stage of the plastic component co-design, to the mold feasibility and its engineering, manufacturing, testing and sampling.

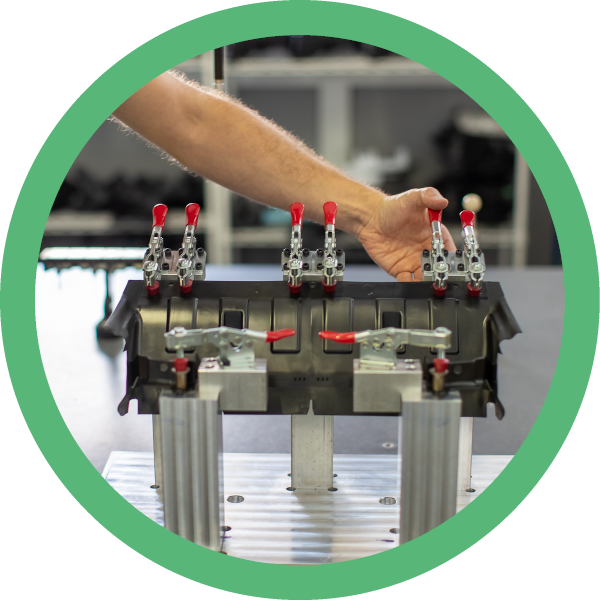

The structure can manage parts production and welding in close simulation of the customer’s production process and has the full capability to perform finished unit measurements, dimensional reports and on-component tests.

CO-DESIGN

Our experience and our designers are at the customer’s service from the first commercial contact, in order to find the right shapes for the desired parts.

CAD & CAM

Thanks to our experience and cutting-edge programs, we offer tailor-made solutions for every need.

MECHANICAL WORKINGS

Using the latest technologies on the market such as 5-axis machining centers with tool magazines and pallet changers, EDM, robotic lathes, internal and external grinding, laser welding machines, we make what was previously just your idea take shape.

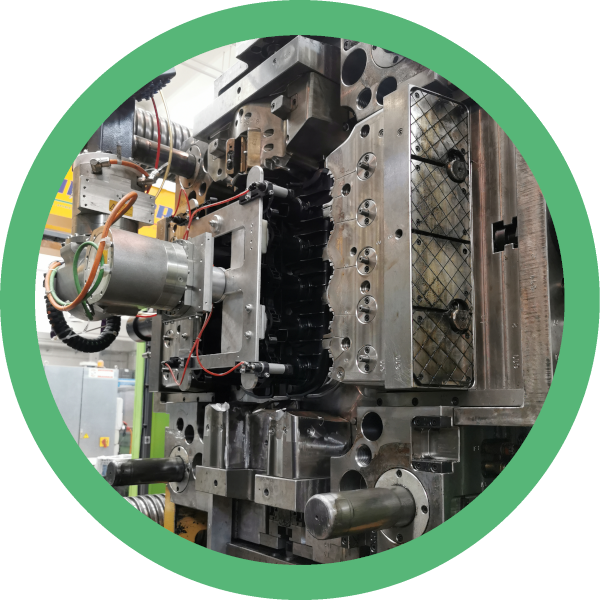

SAMPLING

A state-of-the-art machine park consisting of thermoplastic injection presses from 50 to 1100 tons equipped with manipulators, satellite injectors and rotary tables for 2k molding and gas injections is at the customer’s service to test the equipment designed and built in standard configuration.

METROLOGY

The company has at its disposal a metrology department capable of measuring parts with volumes up to 1m³, and interfacing with the metrology departments of the various customers with software, reports and customized templates.